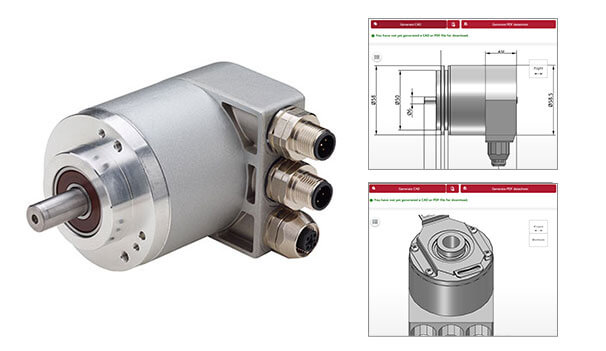

Description

The new AI25 absolute encoder with EtherCAT provides field proven reliability where others fail. Based on the field proven AI25 absolute encoder package, the AI25 EtherCAT provides the best in class shock and vibration resistance (400G shock, 30G vibration), extremely fast cycle times (62.5 μs) and absolute accuracy of ± 35” / (±0.009º) making it the premiere choice for high end automation applications requiring high accuracy and fast speed and position feedback.

Feedback Type

Absolute

Technology

Optical

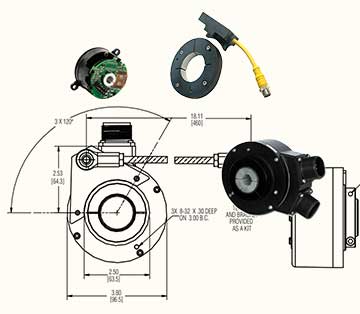

Mounting Configuration

58mm Servo Mount, 2.5" Square Flange, Hubshaft

Encoder Size (Flange)

58mm, 2.5"

Hollow Bore Size

3/8", 1/2", 10mm, 12mm or 14mm

Shaft Size

6mm, 3/8", 8mm, 10mm or 12mm

Housing Material

Aluminum

Max. Operating Speed

10,000 RPM continuous, 12,000 RPM max

Resolution

10-22 Bit Single-Turn, 12 Bit Multi-Turn

Supply Voltage

7 - 30 VDC

Interfaces

EtherCAT

Protection Class (IP)

IP64, IP67

Approvals / Certifications

CE, ROHS, UL

Operating Temperature Range

-40ºC to 85ºC

Storage Temperature

-40ºC to 85ºC

Enviroment

Non-Hazardous