Description

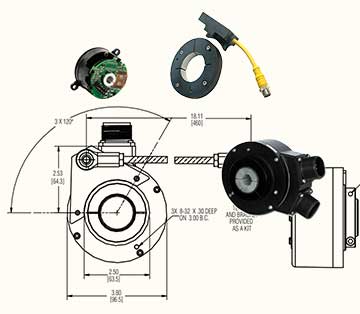

With IEC standard B100 mounting flange and integrated double helix coupling, the EN44 is easy to mount with no additional hardware required. The hubshaft design compensates for motor shaft endplay and allows for shaft speeds up to 6,000 RPM. The EN44 eliminates the hassle of installing an intrinsically safe barrier providing a compact and easy to implement solution for oil & gas.

Feedback Type

Incremental

Technology

Optical

Mounting Configuration

Hubshaft style mount with 4 Clearance holes on the face

Encoder Size (Flange)

>2.5"

Hollow Bore Size

16mm

Housing Material

Aluminum

Max. Operating Speed

6,000 RPM

Resolution

1024 and 2048

Supply Voltage

7-15VDC, 7-26VDC

Interfaces

DLD 4428

Protection Class (IP)

IP67

Approvals / Certifications

CE, ROHS, CSA, ATEX, IECEx

Operating Temperature Range

-50ºC to 100ºC

Storage Temperature

-50ºC to 100ºC

Enviroment

Hazardous