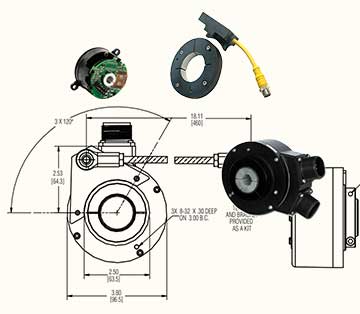

HD25 Heavy Duty Optical Encoder

2.5" OD Heavy Duty Encoder Designed to Survive Extremely Tough Environments

- Size 25 Heavy-Duty Encoder with Single or Dual Isolated Outputs

- Unbreakable Code Disc up to 20,000 PPR

- Special Housing and Seals for IP67 Rating

- Anodized Aluminum, Stainless Steel, or Nickel Plated Housing

- Technical Data

- Accessories

Description

The HD25 heavy duty optical encoder is ideal for machine applications in corrosive environments or that demand stringent wash-downs thanks to its stainless steel housing option. This compact, special-duty encoder is designed to IP67 and NEMA 6 enclosure requirements with a PPR range through 20,000. An intrinsically safe version of the product is available with ATEX, UL and IECEx certifications is also available for hazardous location applications (see HD25 Hazardous Series).General

Mechanical

Electrical

- Open Collector

- Open Collector With Pull-Up

- Push-Pull

- DLD 7272

- DLD 4469

Environmental

Technical Information

Drawing

Certifications

Industries

- Factory Automation

- Off Highway Vehicle

- Oil & Gas

- Vector Motor

- Chemical

- Food & Beverage

- Paper

- Steel and any Other Areas Where a Precise encoder is Needed to Operate in Harsh Environments

Applications

- Top Drives, Iron Roughnecks, Wireline, Logging, Coiled Tubing, Cementing and Fracing/Blenders

- Converting Machinery

- Material Handling

- Packaging Equipment

- Pickling Equipment

- Processing Equipment

- Length measurements

- Motor and drive speed feedback

- Cut-to-length (textile, paper, wood, metal, rubber, plastics, etc.)

- PLC’s and electronic counters