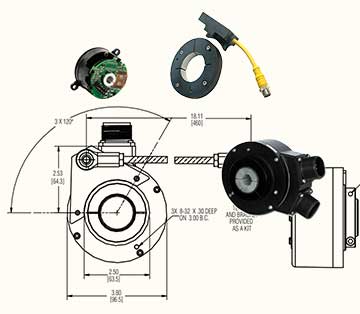

Description

The HSD25 Harsh-Duty Optical Encoder features simple installation on motor or machine shafts. It's often mounted on the non-drive side of the motor where encoder feedback is needed in harsh environment applications. This robust encoder is also available in Stainless Steel to meet NEMA 4X and 6p requirements and its sealed housing allows the encoder to be operated when regulatory wash-down and high pressure steam or caustic chemicals are required. The utilization of an advanced Opto Asic with innovative packaging techniques enables the encoder to operate in high shock and vibration too.

Feedback Type

Incremental

Technology

Optical

Mounting Configuration

Hubshaft mount with 2 different tethers available

Encoder Size (Flange)

>2.5"

Hollow Bore Size

6mm-3/4"

Housing Material

Aluminum, Nickel Finish, Stainless Steel

Max. Operating Speed

5,000 RPM

Resolution

1-20000 PPR

Supply Voltage

5-26VDC

Interfaces

- Open Collector

- Open Collector With Pull-Up

- Push-Pull

- DLD 7272

Protection Class (IP)

IP67

Approvals / Certifications

CE, ROHS

Operating Temperature Range

-40ºC to +100ºC

Storage Temperature

-40ºC to +100ºC

Enviroment

Non-Hazardous