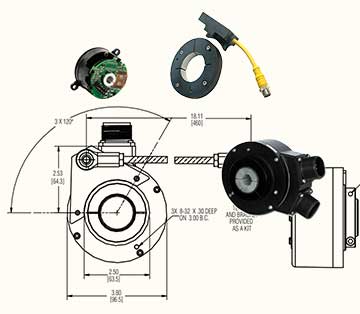

Qube Series 22 Rotary Encoder

Standard 2.25" OD Cube Shaped Encoder with Heavy Duty Reliable Performance

- New phased-array ASIC sensor

- Double the Shaft Loading of Previous Qube

- Expanded Resolution up to 20,000 PPR

- New IP67 Sealing Option

- Unbreakable Code Disc

- Technical Data

- Accessories

Description

The 22 NexGen Qube encoder is built tough for industrial applications like measuring cut-to-length or size for the Textile, Metal, Lumber and Rubber Industries. Its size makes it flexible for use in industrial applications where measuring mechanical motion is critical. The redesign delivers a more rugged encoder. The upgraded features such as increase shaft loading, expanded resolution (20,000 PPR), a phased array ASIC sensor technology which significantly reduces the number of board level components in the encoder and the improved shock spec as well as an improved vibration spec provides a more robust encoder that ultimately allows for a more reliable encoder in an industrial application while increasing product lifetime.General

Mechanical

Electrical

- Open Collector

- Open Collector With Pull-Up

- DLD 7272

Environmental

Technical Information

Drawing

Marketing Materials

Certifications

Industries

- Factory Automation

Applications

- Measuring cut to length or size for textile, metal, lumber, and rubber industries

- Tracking, storage and retrieval, pick and place, conveying and elevating for material handling applications

- Winding, including films, foils, wires and extrusions

- Measuring mechanical vibration for processing, labeling, filling, mixing, batching, and packaging

- Position control, for flexible and automatic assembly equipment

- Speed feedback for precise drive and machine monitoring and control